| PRODUCTS |

| |

|

MFRS.

OF PRECISION

MACHINE COMPONENTS FOR |

|

Petrochemical

Industries |

|

Aero Space

|

|

Defence |

|

Pharmaceutical |

|

General

Engineering |

|

| |

| |

| PRECISION-MACHINED

COMPONENTS |

| |

|

Repeatability

and well-controlled tolerances are hallmarks of precision

machining. Components, parts and finished durable products

that are designed to maintain extremely tight tolerance

margins and a high degree of durability are essential and

common drivers for utilization of precision machining |

|

| |

| |

| |

| |

PRECISION-DIE

A compound die allows the cutting of internal and external

part features on a single press stroke.

|

|

|

| |

| |

| |

| INSTRUMENTATION

TUBE & PIPE FITTINGS |

| |

|

FEATURES

:-

• Rugged

Forged Body or Bar Stock body construction.

• Variety

of End Connections: 1/8” to 1” Ferruled Tube Fittings and

up to 2” Threaded Pipe End Connections.

• Materials

of Construction: SS 316, Brass, Inconel, Alloy-400, Hastelloy

- C276 etc.

• Working

Pressures: Upto 10000 PSI in Tube Fittings and 20000 PSI

in Pipe Fittings

• NACE

Certification available upon request

• Complete

Heat Code traceability |

|

| |

| |

| |

| INSTRUMENT

VALVE MANIFOLDS |

| |

|

2

Valve Manifold

3 Valve Manifold

5 Valve Manifold

FEATURES :-

•

2 Valve Instrument Manifolds designed for Liquid Level

and Static Pressure applications.

•

3 and 5 Valve Instrument Manifolds designed for Differential

Pressure Applications

• Rugged

One - Piece Forged Body construction

• Maximum

working pressure up to 6000 PSI (413 bar) at |

|

38 C(100 F) with PTFE Stem packing.

• Temperatures

up to 640 C / 1200 F with Graphite stem packing (M & MV Series

only)

• Metal

to metal Bonnet to Body Seal

• Flange

design as per MSS - SP - 99

• Standard

Flange Seal is PTFE and Graphite for High Temperature applications.

• MOC:

SS 316L, Carbon Steel, Monel - 400 and Inconel etc.

• Optional

Sour Gas service available conforms to N.A.C.E. MR-01-75-90 |

| |

| |

| |

| NEEDLE

VALVES |

| |

|

•

IB Series - Integral Bonnet

• HB

Series - Hex Body

•

SB Series - Square Body

•

UB Series - Union Bonnet

FEATURES :

• Rugged

One - Piece Compact Forged Body construction for

• High

Strength and Easy Maintenance

• Straight

and Angle Flow Pattern

•

Materials of Construction: Stainless Steel, Carbon Steel,

Brass, Inconel, Alloy 400, Hastelloy etc.

|

|

•

Working Pressures up to 6000 psig (413 bar) at 200 C

• Variety

of End Connections: NPE Single/Twin Ferrule Tube End,

• NPT,

ISO, DIN and JIS pipe threaded

• Size

Range: 1/8” to 1” Tube End and Male/Female Threaded

• Pipe

End Connections |

| |

| |

| |

| MULTI-APPLICATION

BALL VALVES |

| |

FEATURES

:

•

3-Piece Compact Design, Precision Machined and Rugged Construction.

• Full

/ Reduced Bore for High Flow Capacity.

• Working

Pressure: Upto 710 BAR (10000 PSI).

•

Temperature Range: -39 F to 300 F (-39 C to 150 C).

•

Variety of Materials: SS316, Hastelloy, Inconel, Brass,

Alloy 400 and Carbon Steel etc.

•

Annealed bodies conforming to NACE MR-01-75 for Sour Gas

Service Application.

•

All vetted parts are compatible

with CNG (Compressed Natural Gas) and H2 (Hydrogen).

|

|

|

•

Pneumatic and Electric Actuation

options available Series of End Connections: NPE Single/Twin Ferrule

Fitting End,

• NPT,

ISO, DIN and JIS Pipe Threaded. Size Range : 1/8” to 1” and 3mm

to 25mm Tube Ends.

• 1/8”

to 1” Male/Female Threaded Pipe Ends. |

| |

| |

| |

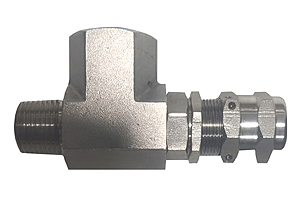

| CHECK,

RELIEF & NON-RETURN VALVES |

| |

|

FEATURES

:

• Soft

Seat for Bubble Tight shut-off

• Heavy

duty, corrosion resistant springs for long life

• Large

Orifice for maximum flow and low Pressure drop

Pressure

Rating:

• 6000

PSIG (400bar) at 200° C with VITON Seals

• 1/4”

to 1” NPT, BSP Male or Female threaded ends, or double

ferruled tube fitting ends

• Variety

of Materials:

Stainless Steel, Carbon Steel, Brass, Hastelloy C-276,

Inconel ,625 and Alloy 400 etc.

• 100

% Pressure tested for Crack and Reseal performance as

per MSS-SP-99 |

|

| |

| |

|

| |